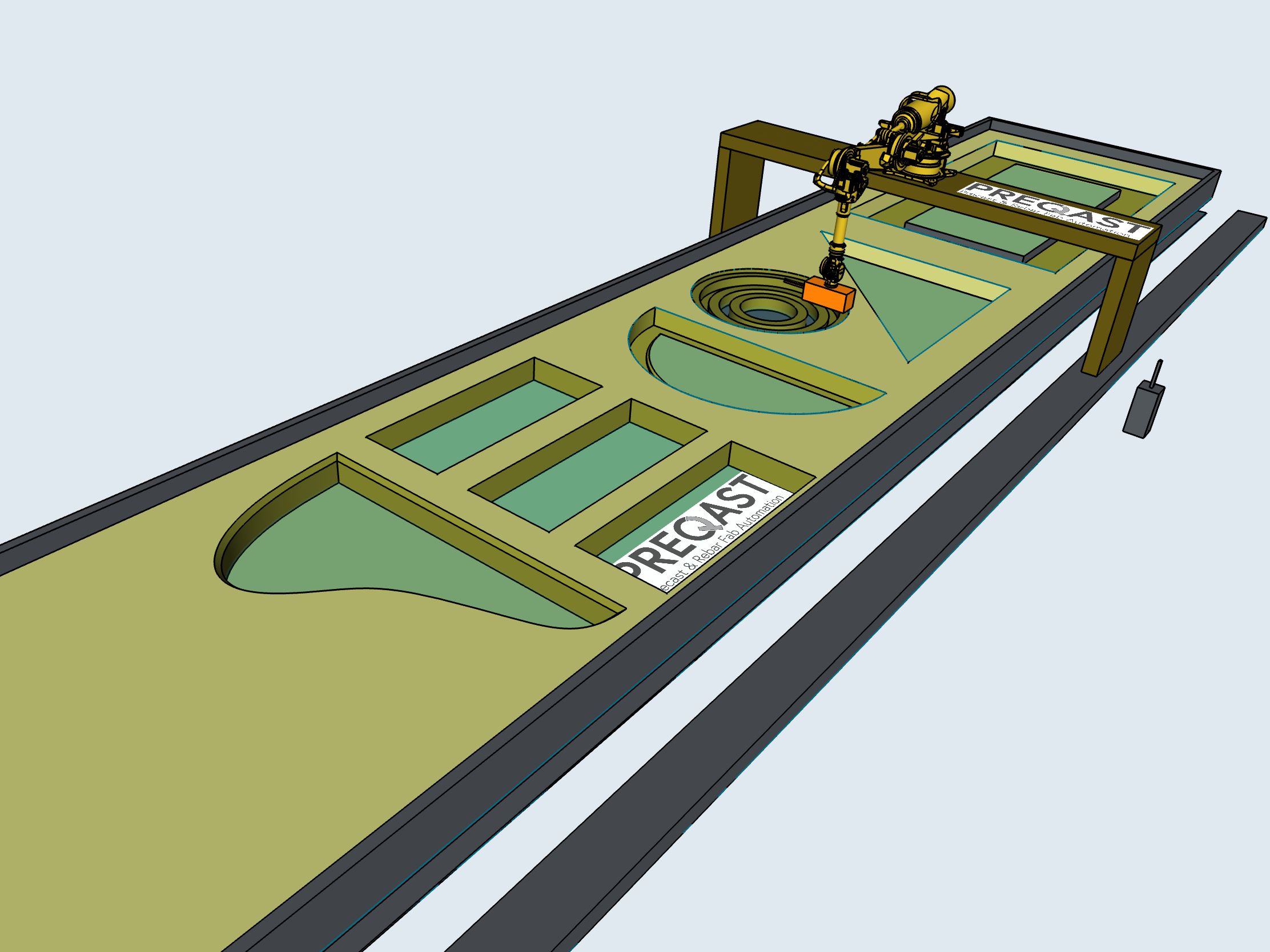

Large precast concrete slabs such as ceiling and wall slabs, as well as balconies are nowadays produced on long production tables or pallet-shaped tables.

For some years now, there have been ideas of making moulds in wax or sand, filling the formwork tables with either material and then milling the moulds with a 6- or 7-axis milling machine.

Although this process is theoretically conceivable, it requires an extremely long processing time, because approximately 80-90% of the volume have to be removed.

Only the external volumes of the precast concrete parts are introduced in the form of oversized wax formwork. The defined contours of the precast concrete parts are smaller than the original ones. Therefore it allows the edge surfaces of the mould to be milled too.

The an important next step the wax will be prepared for the digital process.